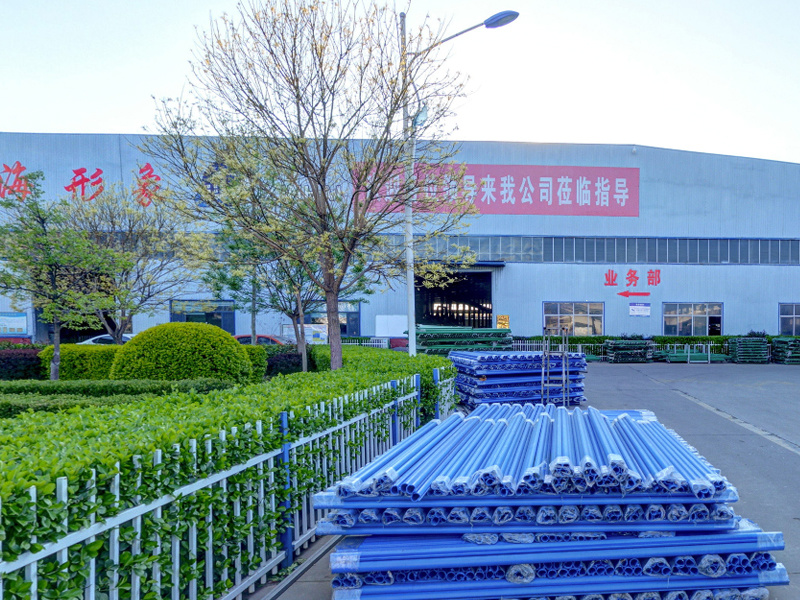

Let's talk about the functions and purchasing considerations of highway guardrail nets.

Dec 09,2022

Let's talk about the functions and purchasing considerations for highway guardrails

1. Highway guardrails separate motor vehicles, non-motorized lanes, and non-motorized traffic. They vertically separate the highway in cross-section, allowing motor vehicles, non-motorized vehicles, and pedestrians to travel in their respective lanes, thereby enhancing road safety and optimizing traffic management.

2. Highway guardrails prevent traffic behavior, stopping pedestrians, bicycles, or motor vehicles attempting to cross the road. They require the guardrail to have a certain height, density, and strength.

3. During installation, the shape of the guardrail should be concise and light, reminding drivers to be aware of the guardrail's presence, as well as pedestrians and non-motorized lanes, to prevent traffic accidents.

4. Based on the different materials, styles, shapes, and colors of highway guardrails, harmony and coordination with the highway environment can be achieved.

Here are several aspects to consider when purchasing guardrails:

1. Distinguish and choose the correct type of highway guardrail

Highway guardrails can be selected according to their purpose. Different types of guardrails have significant price differences, so it's crucial to choose the highway guardrail that suits your needs. To distinguish between them, it's better to learn some professional knowledge; otherwise, what you buy at a high price might not necessarily be practical.

2. Mesh size ratio

Besides affecting usage, mesh size directly relates to the guardrail's quality and price. Therefore, mesh size is a crucial parameter for inspection. However, if the boss is easy to talk to and not short on money, then it's hard to make a prediction.

3. Wire diameter

The wire diameter is related to the amount of raw material used and is a crucial parameter determining the guardrail's quality and price. The special tool for accurately measuring the wire mesh diameter can be a coating thickness gauge or a micrometer. If you don't have one, buy one; after all, it's only a few tens of yuan. The potential loss if not measured accurately would be much more than that, so some investment is definitely necessary.

4. Surface coating quality

Highway guardrails generally require surface treatment to prevent corrosion and extend their service life. Common coatings include hot-dip galvanized coating, electrostatic spraying coating, phosphating coating, hot-dip zinc coating, and others. Although you may not know all of them, it's always good to understand more basic common sense.

Here are a few tips for identifying anti-corrosion quality: Hot-dip galvanizing is superior to phosphating; both types can be distinguished by appearance, with the former appearing whitish and dull, and the latter shiny. Hot-dip zinc coating has a thicker plastic layer on the surface, offering better corrosion resistance. Electrostatic spraying provides a smooth, bright, and aesthetically pleasing surface. For guardrails that come into contact with liquids, plastic coating is better than phosphating. For those exposed to sunlight for a long time, hot-dip galvanizing is superior to plastic coating, and so on.

5. Other material specifications

There are many types of guardrails, and their manufacturing methods and materials used also differ. It's important to note the selection of the guardrail frame; some reputable large enterprises use angle steel and round steel, and the choice of angle steel and round steel for different positions should vary.

Contact Us

E-mail :

Phone/WhatsApp/WeChat:

Address:

No. 12, Jing Si Road, East Industrial Park, Anping County, Hengshui City, Hebei Province